| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : SANKON

Model Number : CUSTOMIZED

Certification : ISO9001/CE

Place of Origin : CHINA

MOQ : 1SET

Price : USD1~47000/SET

Payment Terms : L/C, T/T

Supply Ability : 120SETS/YEAR

Delivery Time : 3MONTHS

Packaging Details : SUIT FOR SHIPPING

Name : Ball Mill

Rated Voltage : 380V

Brand : SANKON

Certificate : ISO9001/CE

Packing type : Suit for shipping

After-sales service provide : Engineers available to service machinery overseas, Field maintenance and repair service, Field installation, commissioning and training, Online support

SANKON Building Materials Technology Co. LTD is a one stop solutions provider for autoclaved aerated concrete (AAC) production equipment including complete AAC production lines.

Based on the knowledge about the AAC panel production line and AAC block production line, as well as abundant experiences about equipment manufacturing, we are able to provide clients some customized equipment according to the needs. We can provide fast and reliable solution no matter you want to replace some old equipment or you want to upgrade the production line.

Introduction:

Ball Mill is a key equipment to grind all kinds of ores and other materials. Which is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc

It can suit dry mill and also wet milling, usually depend on the materials and its usage.

The application area is very widely, as long as the requirement for smaller powder size making purpose.

Ball mill desigh:

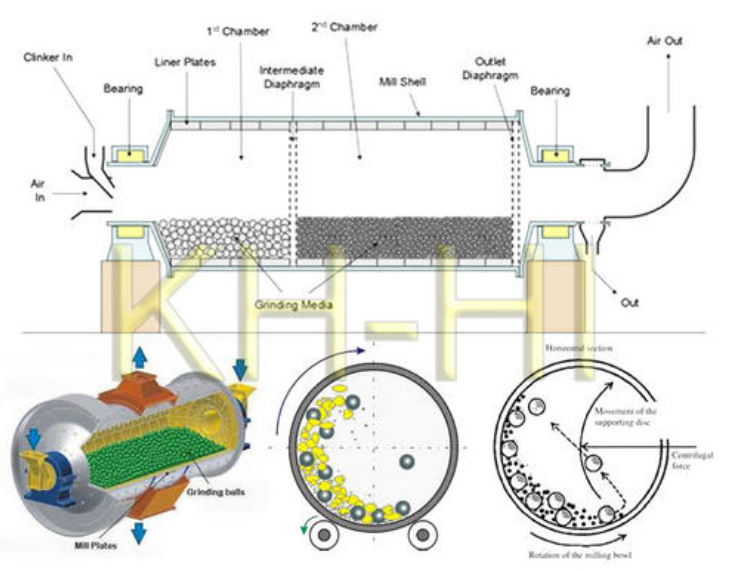

Ball Mill consists of feed&discharge parts, rotary shell, transmission part and other major components. Hollow shaft is with steel parts, lining is removable. Rotary gear adopts casting hobbing, and the tube body is with resisting liner.

The spare parts:

Liners and balls can choose different materials according to different usage.

Working Principle:

The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel. There are two chambers and grid of ball mill. Material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The ball mill shell rotates so as to generate electricity, and this force brings ball to a certain height and then balls drop down by gravity, the impact is the grinding force to the material. After the primary grinding, materials go into the second chamber through segregate screen. In ball mill second chamber, there are flat liners and steel ball. After the secondary grinding, material is discharged from the discharging mouth. Then the whole grinding process is ended.

Ball Mill Advantages:

1. High efficiency of grinding

2. Low failure rate

3. Prosper design

4. Convenient usage.

Technical parameters:

Model | Cylinder speed(r/min) | Ball capacity (t) | Material-in size(mm) | Material-out size(mm) | Capacity(t/h) | Motor power(kw) | Weight(T) |

Ø900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 15 | 4.2 |

Ø900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Ø1200×2400 | 37 | 3.8 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 11.5 |

Ø1200×3000 | 37 | 5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Ø1200×4500 | 37 | 6.6 | ≤25 | 0.074-0.4 | 1.6-5.8 | 45 | 13.8 |

Ø1500×3000 | 29.7 | 8 | ≤25 | 0.074-0.4 | 2-5 | 75 | 16 |

Ø1500×4500 | 29.7 | 12.5 | ≤25 | 0.074-0.4 | 3-6 | 90 | 22 |

Ø1500×5700 | 29.7 | 15 | ≤25 | 0.074-0.4 | 3.5-6 | 110 | 24.7 |

Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

Ø1830×4500 | 25 | 15.8 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Ø1830×6400 | 24.1 | 23 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 36.5 |

Ø1830×7000 | 24.1 | 24 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 39 |

Ø2100×3000 | 24.6 | 20 | ≤25 | 0.074-0.4 | 7.5-3.6 | 180 | 40 |

Ø2100×4500 | 24.6 | 22.5 | ≤25 | 0.074-0.4 | 7.5-40 | 210 | 48 |

Ø2200×6500 | 21.7 | 25 | ≤25 | 0.074-0.4 | 10-12 | 380 | 52 |

Ø2200×7000 | 21.7 | 28 | ≤25 | 0.06-0.08 | 10-14 | 380 | 54 |

Ø2200×7500 | 21.7 | 29 | ≤25 | <0.08 | 12-14 | 380 | 56 |

|

|

High Quality Block Making Machine, Brick Machine for AAC Production Line - Ball Mill Images |